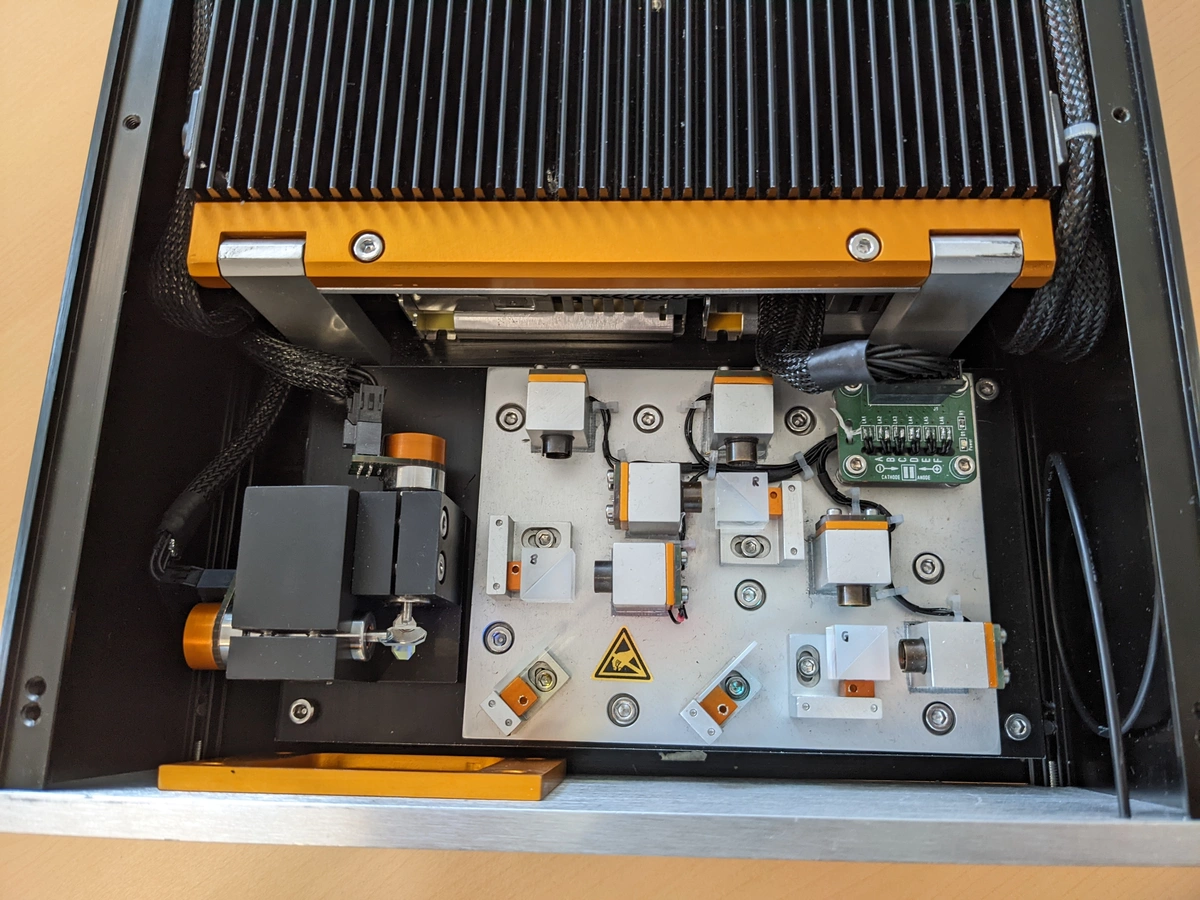

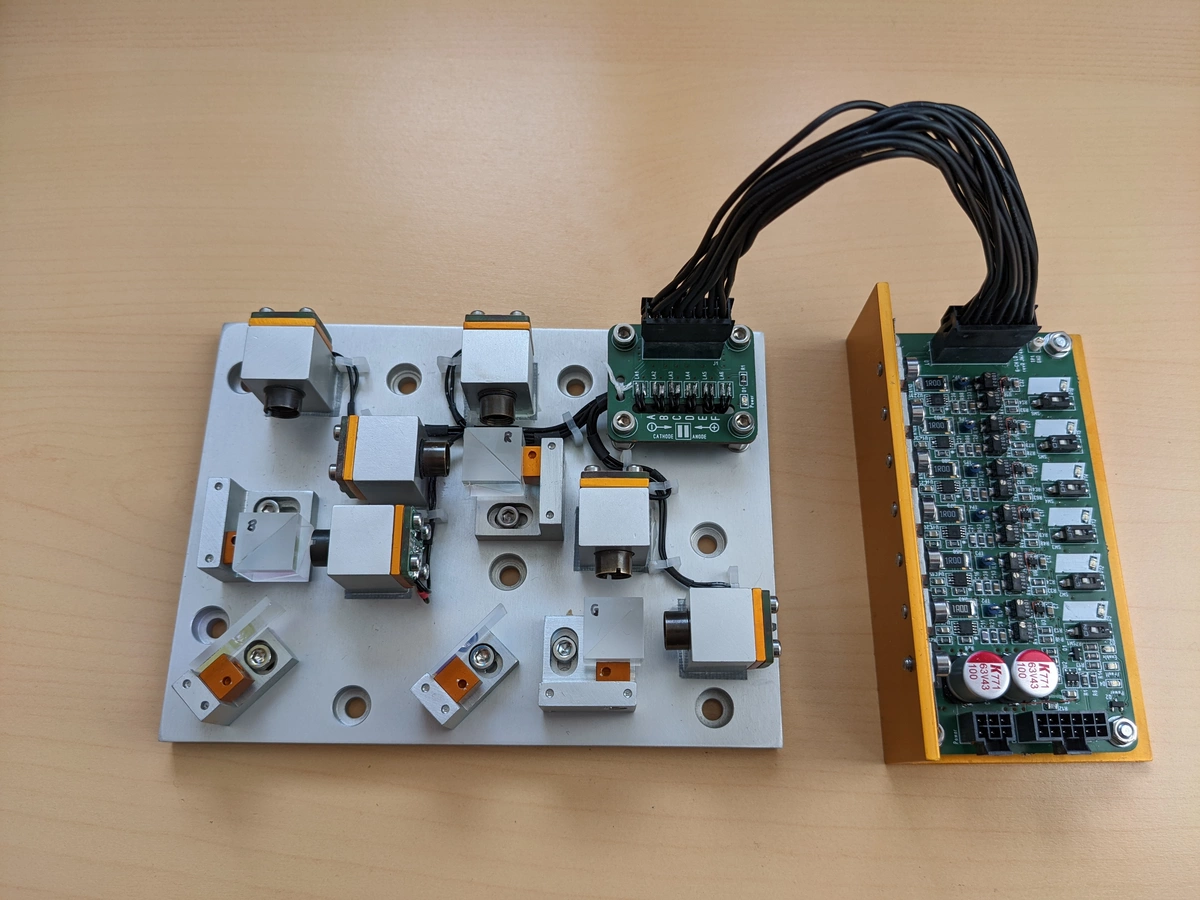

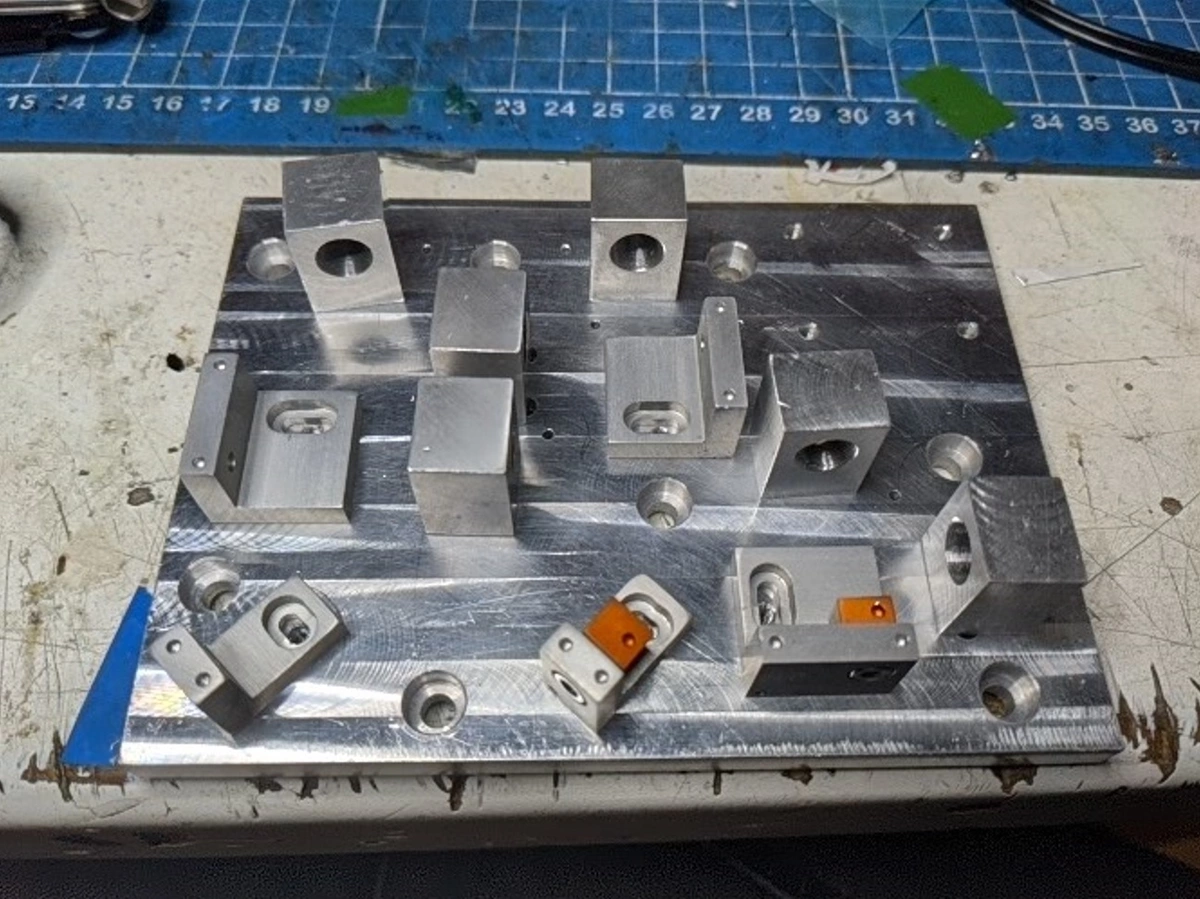

I designed a compact 6 channel laser diode driver for this project. Each channel can supply up to 2A continuous forward current, with emission linearization by adjustable offset current. The offset current is clamped to zero when the modulation signal drops below 100mV to suppress standby glow. Input voltage is monitored by an on board power supply watchdog. Laser emission is only enabled if the power supply has been in the valid voltage range. Additional start delay was implemented to allow the circuitry to settle and reject power up transients. When power is disconnected the lasers are safely steered into the off position before the control circuitry is shut down. An electronic shutter input crowbars intermediate modulation levels and disconnects all laser diodes through a redundant high side switch. The shutter input is resistant against input stage overload.

The driver achieves roughly 300kHz modulation bandwidth. Each channel can be switched to CW operation using on board DIP-switches. A voltage output forward current signal is available through buffered test points.

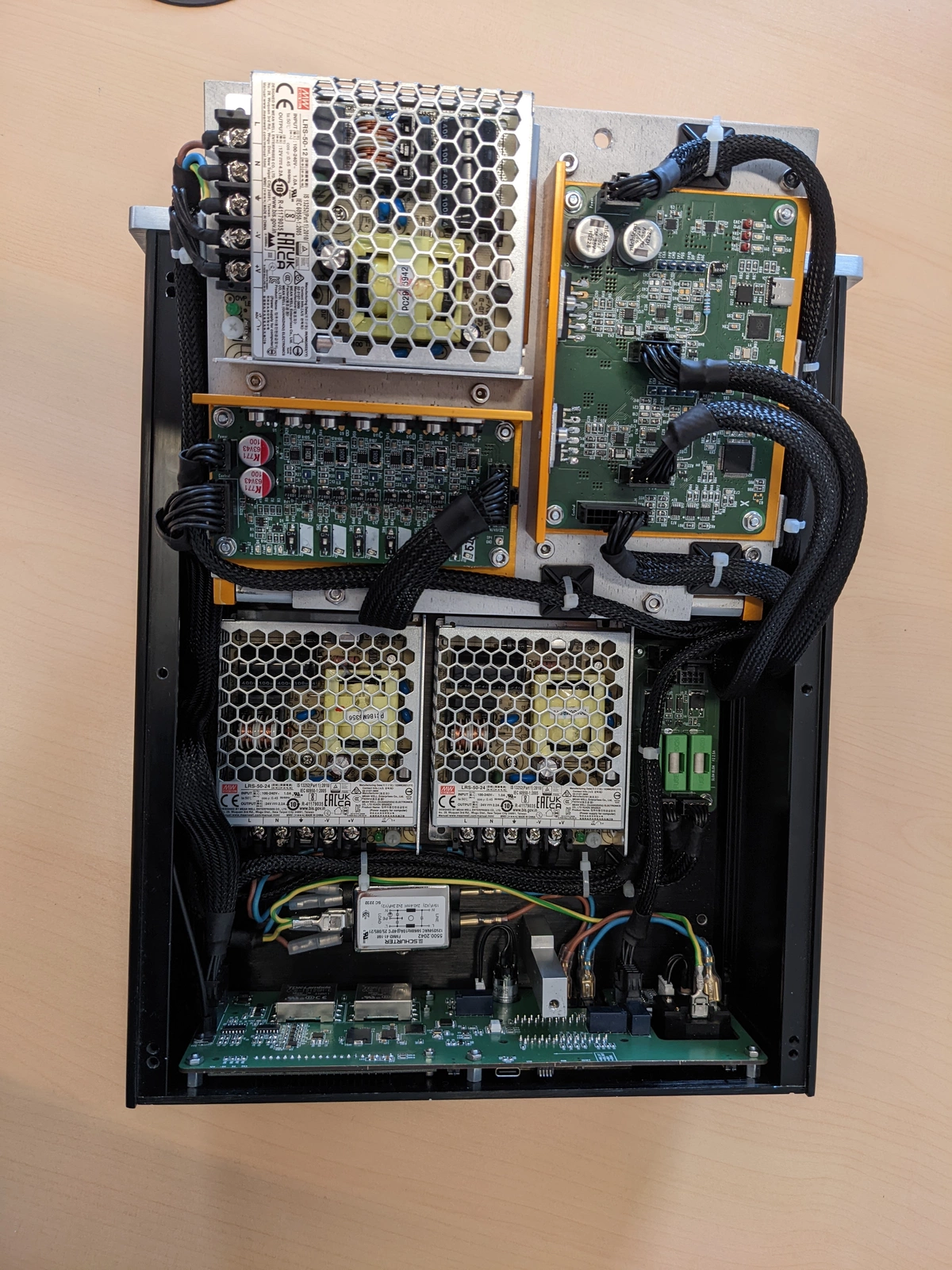

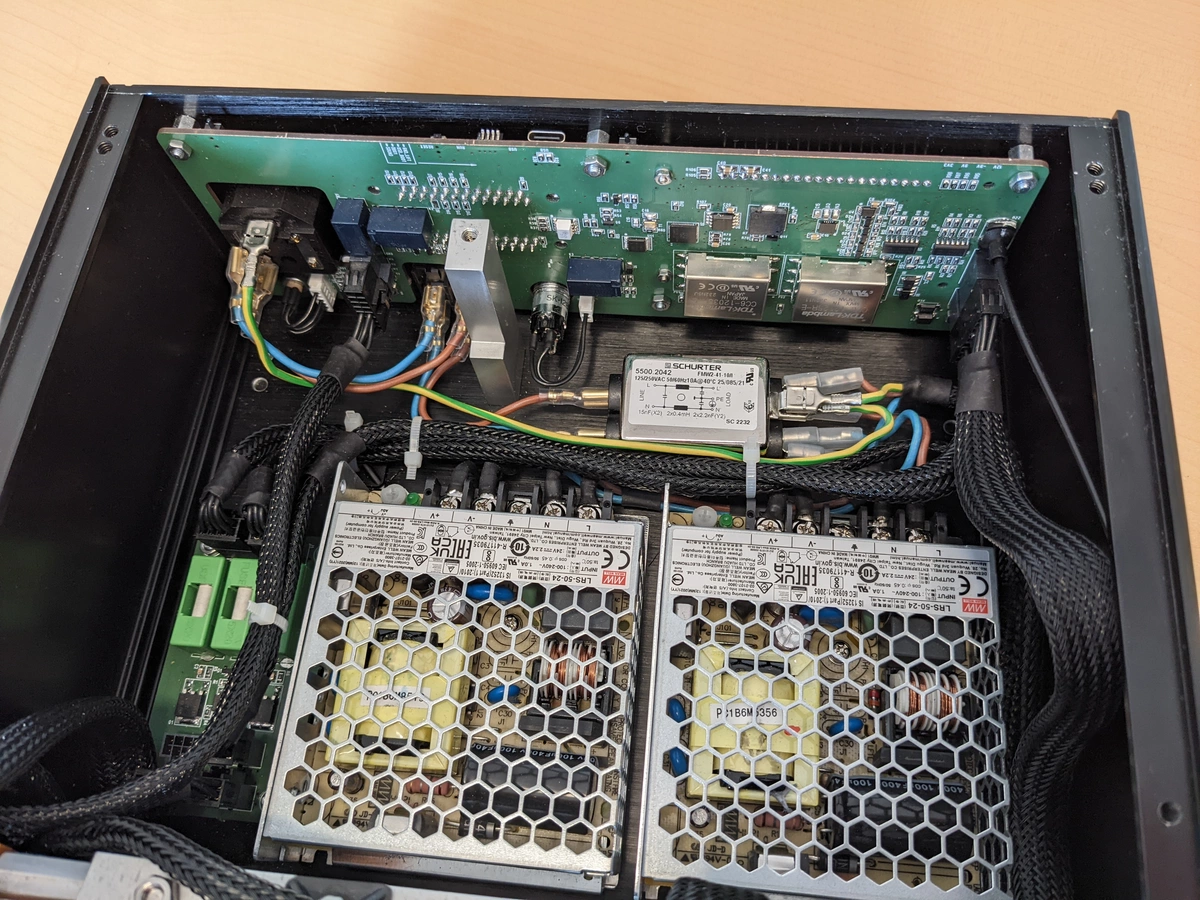

I designed a large PCB for the projector backplane. It handles interfacing to the ILDA ISP DB25 connector. Modulation signals from the projector controller are converted to single ended using differential receivers. X/Y inputs are daisy-chained to an output connector and can be flipped along X/Y/XY using relay logic. ILDA TTL is opto-isolated and can be ground-lifted. ILDA interlock, estop, emission indicators and redundant case interlock switches and scanner monitoring were implemented for safety. I added backlit buttons and an OLED-Panel to make everything look pretty.