I wanted to experiment with electric motors, so I built a motorized soapbox-style car powered by a 4.5 kW brushless drivetrain.

The project uses a compact EV drivetrain design in a lightweight chassis, and being so close to the ground makes it surprisingly quick and fun to drive.

I designed the gearing to favor torque over top speed, allowing the vehicle to accelerate quickly. While the car reaches a top speed of just over 50 km/h, it delivers strong torque across most of the powerband.

Using a plastic vehicle as a base introduces limitations, as the original chassis lacks the stiffness and features required for stability under high acceleration.

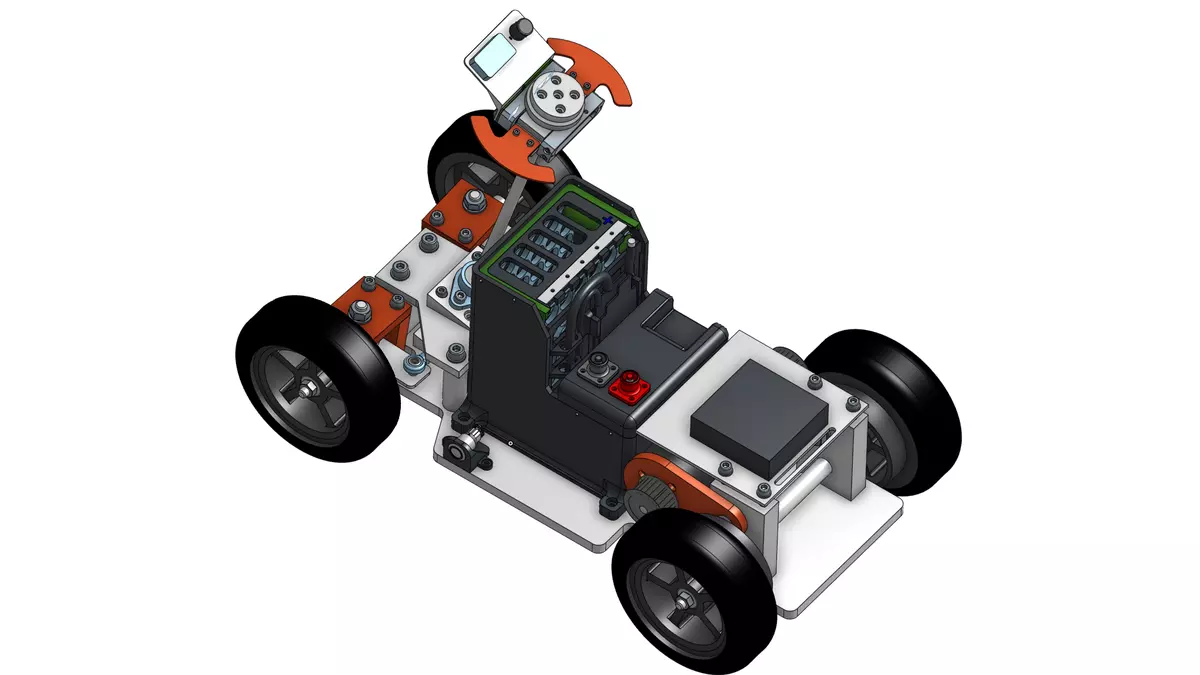

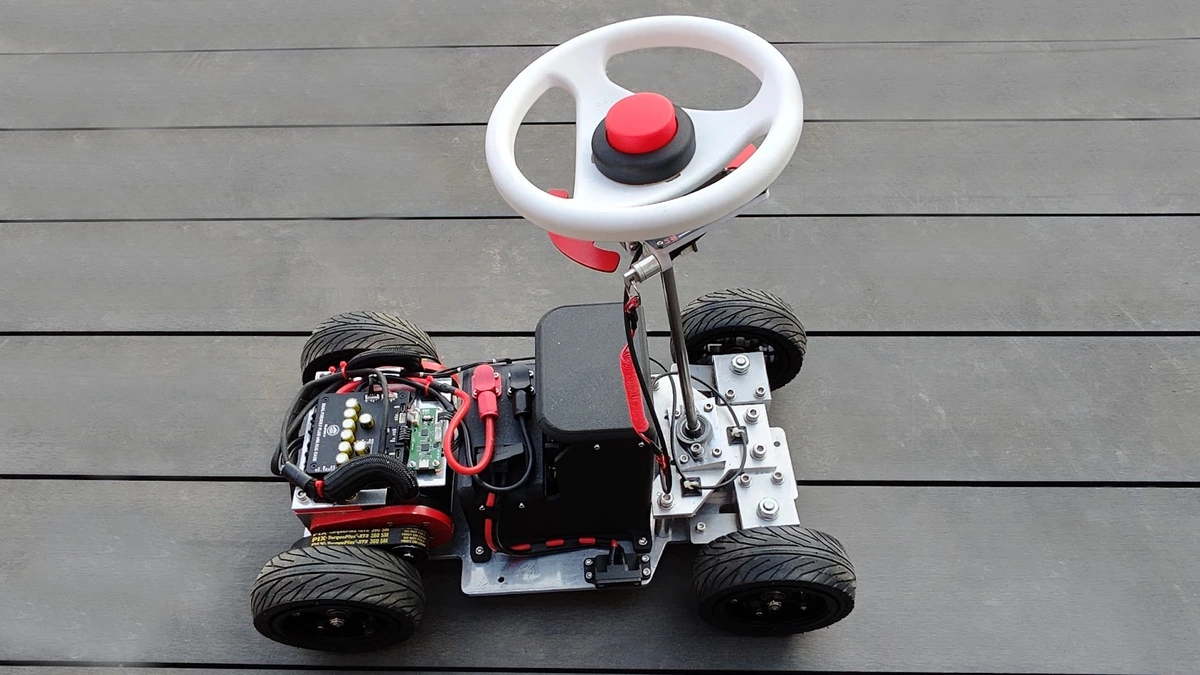

To address this, I replaced all structural components with a custom-fabricated chassis. I also implemented a custom instrument cluster and throttle assembly that provide odometry data and throttle mixing.

I replaced the original solid plastic wheels with air-filled tires designed for electric longboards, mounted on alloy rims.

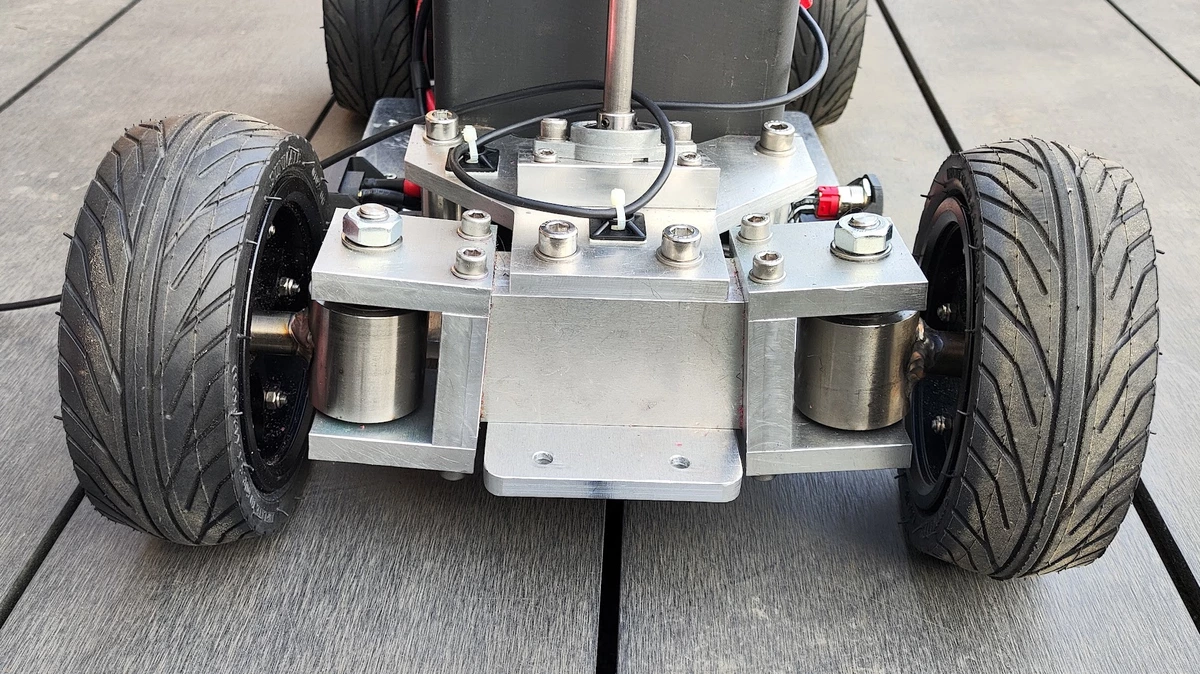

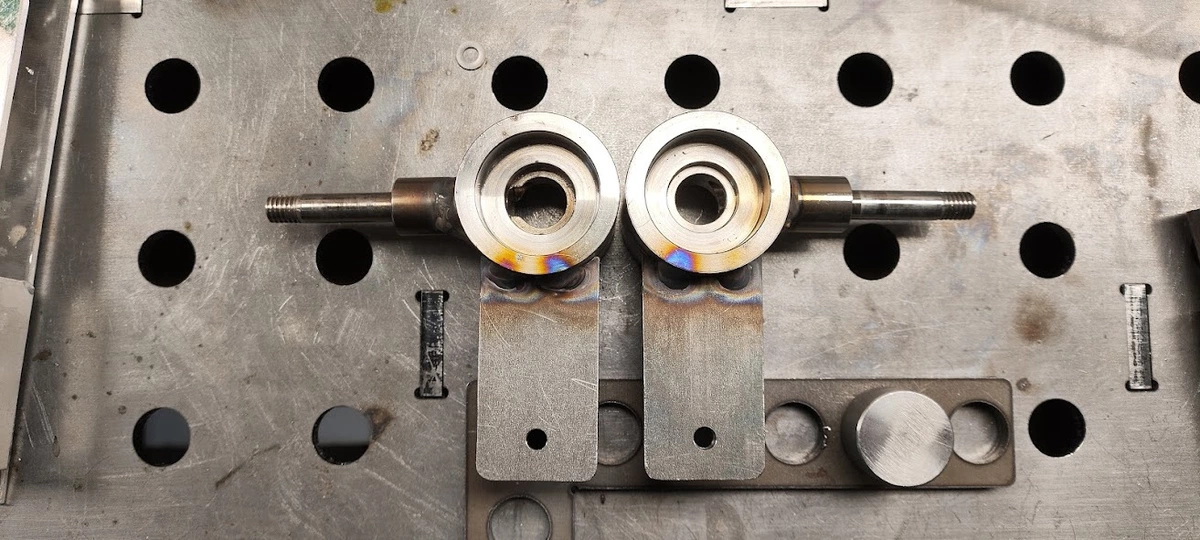

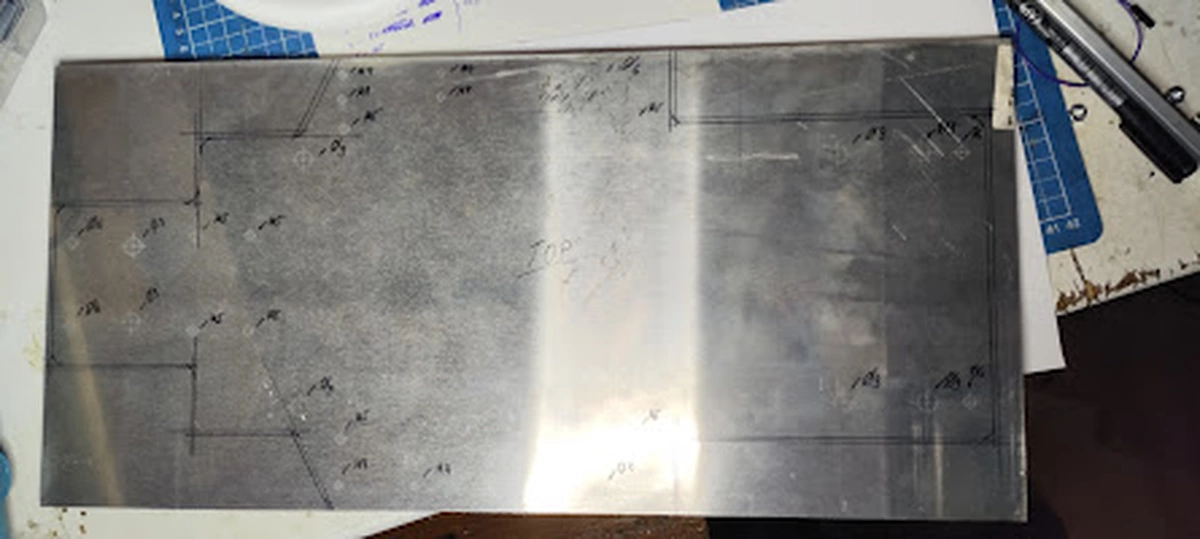

The steering knuckles were machined from stainless steel and welded together. A 5° caster angle and 8° kingpin inclination were incorporated, along with a dynamically adjustable toe angle to improve handling.

The steering column is mounted using flange bearings and can be adjusted along the vehicle's longitudinal axis to accommodate the plastic body.

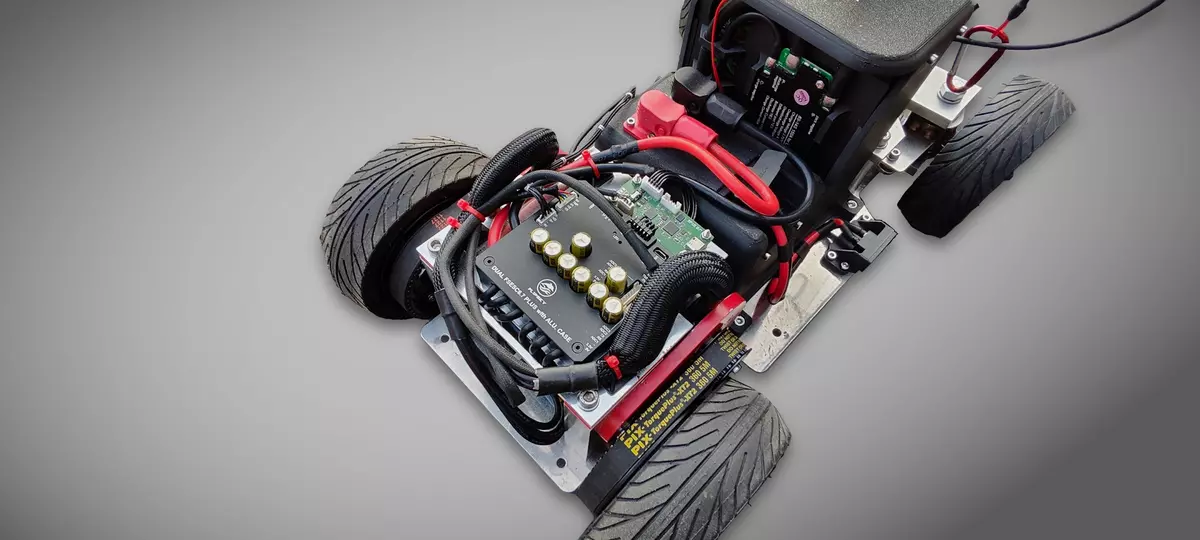

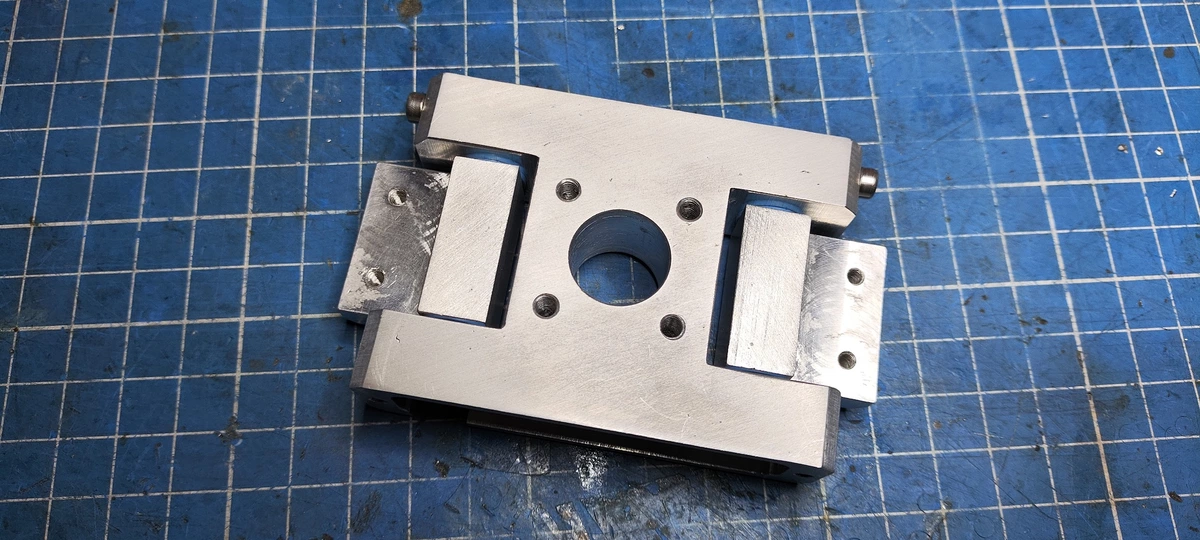

The wheels are driven by two electric motors using timing belts. I machined motor mounting brackets with eccentric cams for adjusting belt tension. The rear axle was machined from stainless steel. Braking

also works through the electric motors. The ESC was programmed with a throttle curve to stabilize the vehicle, as directly applying the full drive power at low speed results in uncontrollable acceleration.

With some ESC tuning, the vehicle is suprisingly easy to drive and quite stable. Retrospectively, I could have probably gone for a faster gearing and would've still had enough torque.

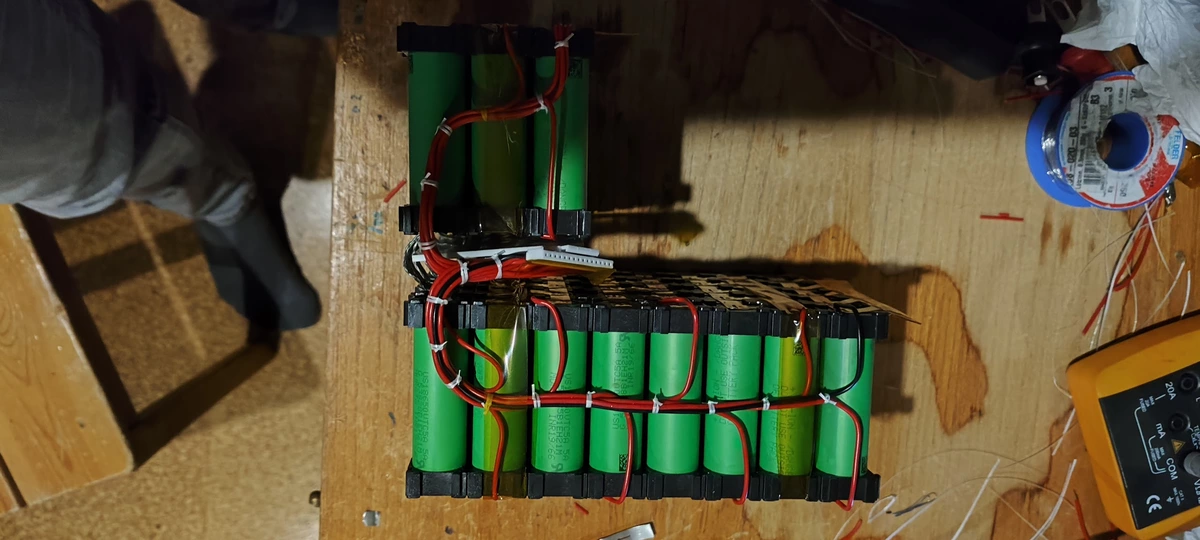

I built a custom Li-Ion battery pack for this project from high current 18650 cells. The battery pack is capable of delivering surge currents exceeding 150A at 11s.

A BMS (Battery Management System) ensures proper charge balancing and battery health. The cells were spot-welded, and the enclosure was 3D-printed. I also printed TPU shock absorbers

for mechanically isolating the battery from the rigid mount axles.

The battery is centrally mounted to maintain weight distribution. This setup keeps the center of gravity close to the vehicles center point. Fitting the battery into the chassis was a challenge

and a key reason for designing a custom pack.

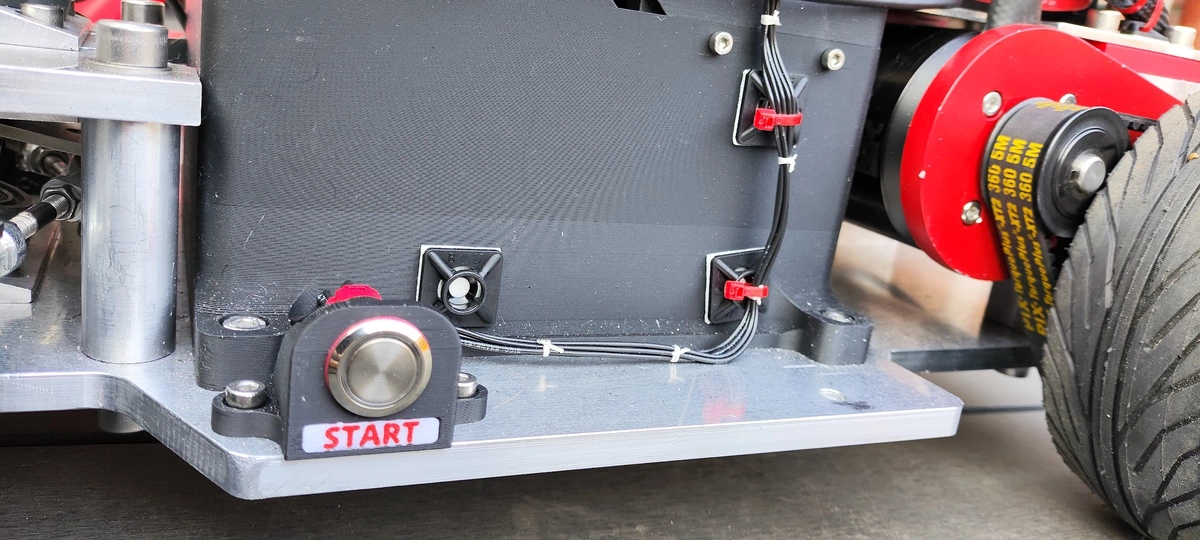

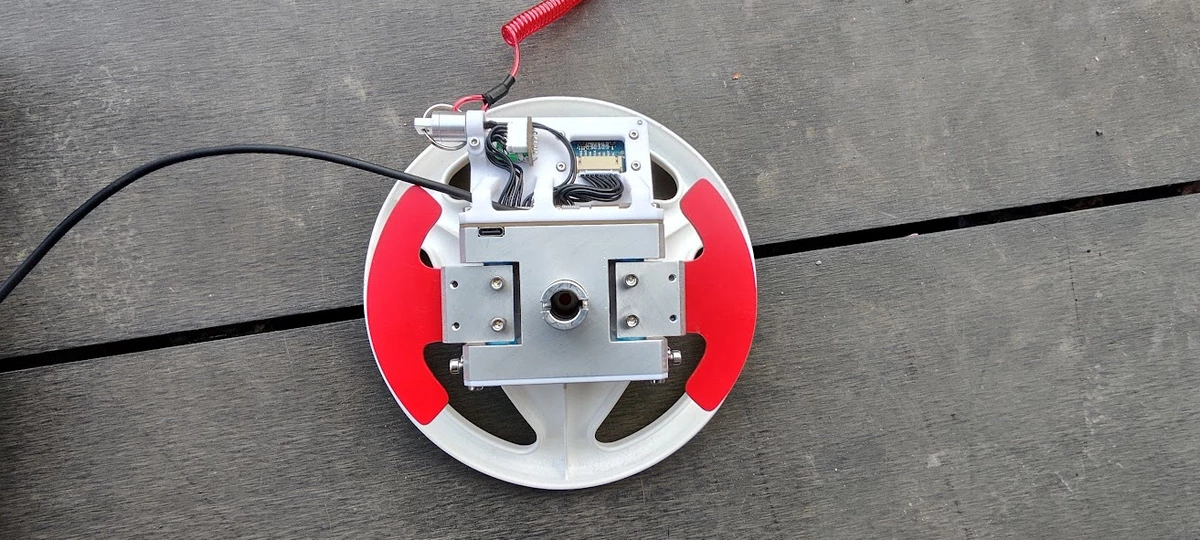

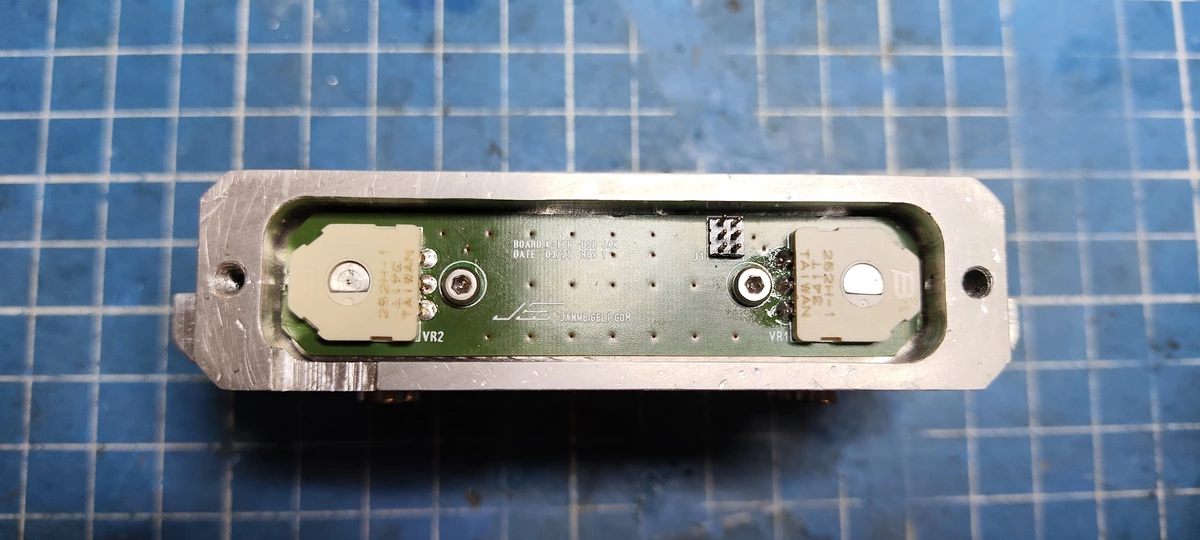

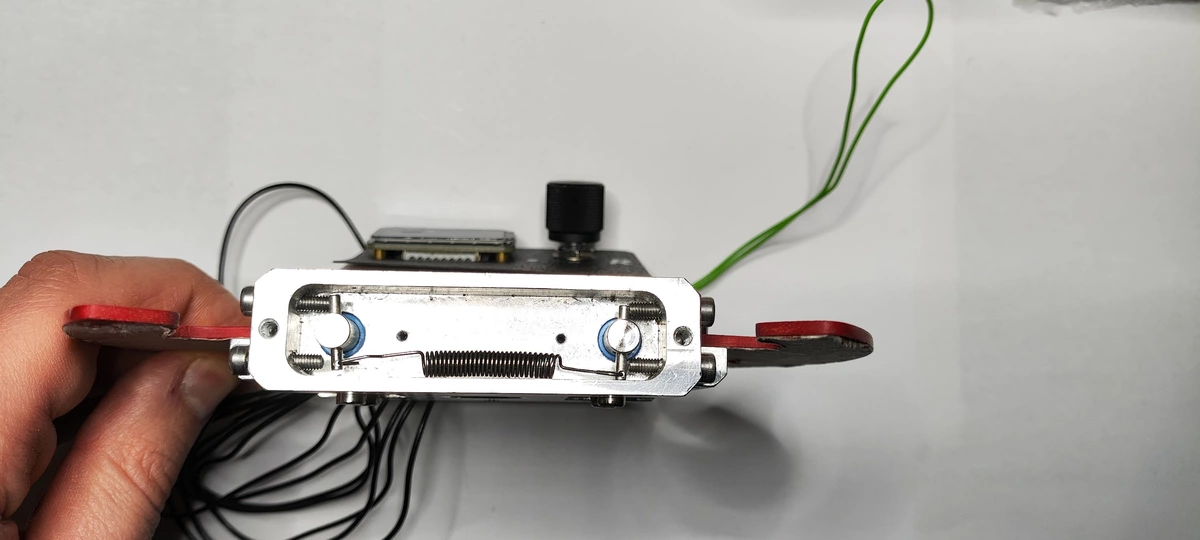

I designed custom controls for the vehicle with two separate steering wheel levers for braking and throttle control. The lever mechanism was machined from aluminum, the levers were made from fiber glass.

A magnetic connector functions as a engine cutout switch.

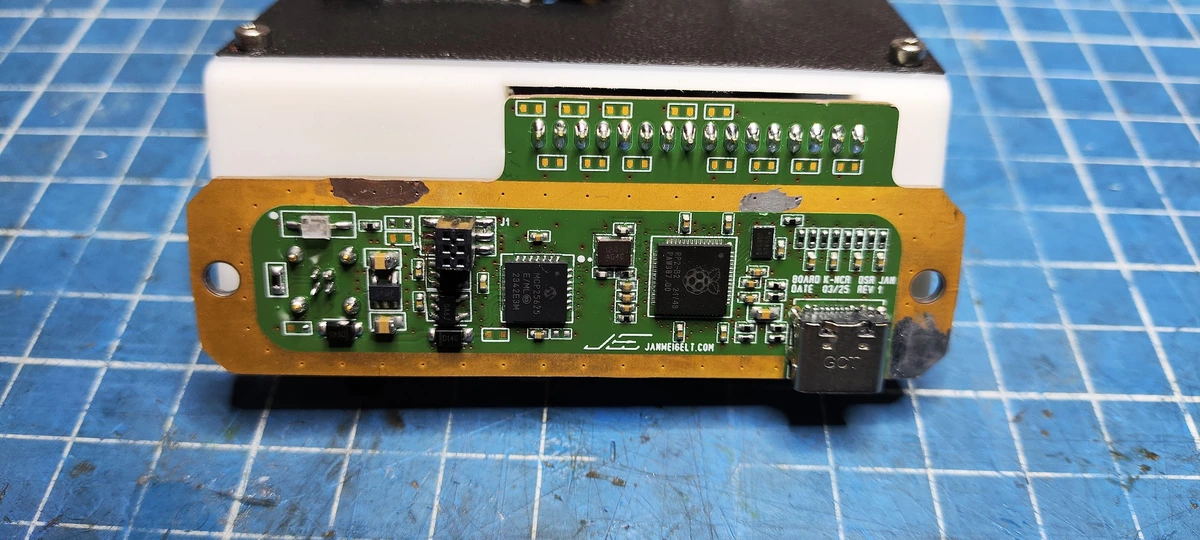

A custom control board interfaces with all controls, a TFT display, and the motor controller via CAN bus communication. I used the LVGL library to implement an UI for displaying

odometry data and configuring the vehicle.

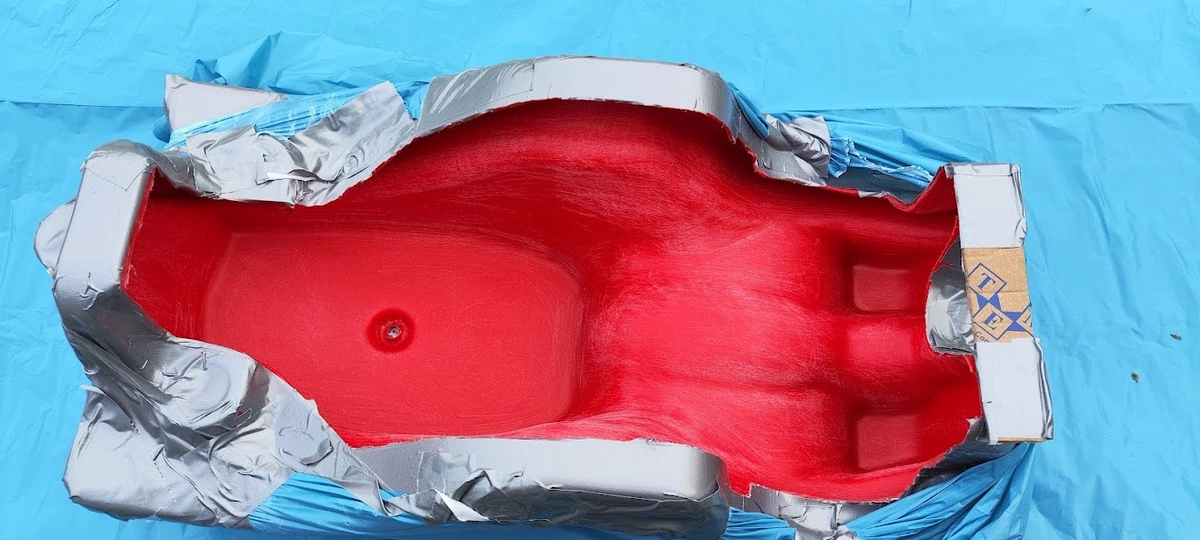

I modified the original vehicle by removing its bottom section to make room for the new drivetrain. While the plastic body is reasonably stable on its own, removing the bottom significantly reduced its rigidity.

I had initially planned to add a fiberglass layer, but the body proved surprisingly stiff. To reinforce the structure, I instead filled the thin side sections with rigid expanding foam.

Nuts were then riveted to the plastic body, creating six mounting points for bolting to the chassis. Finally, the vehicle is mounted on an 8mm aluminum plate to provide additional rigidity.