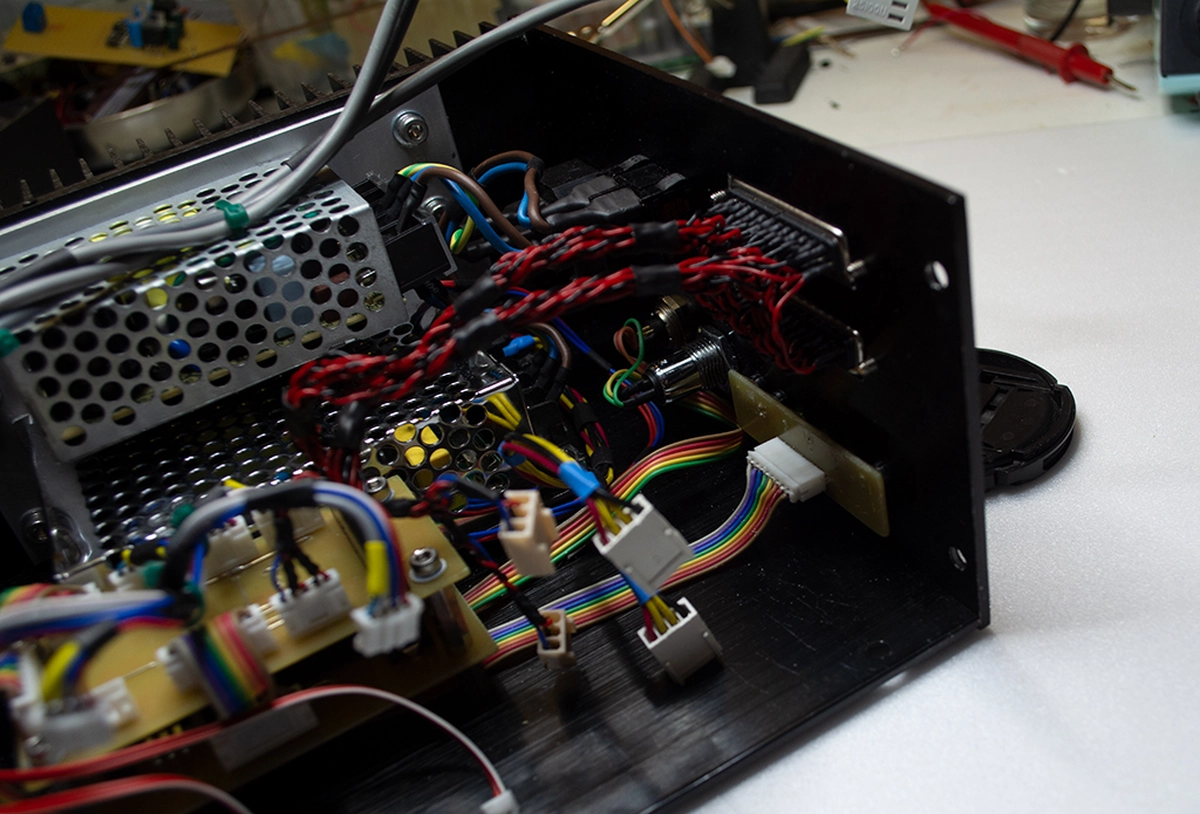

I built this compact, low cost laser projector around a cheap beam steering assembly I had from a previous build. It is a compact tabletop unit with a total of around 200mW single mode emitters.

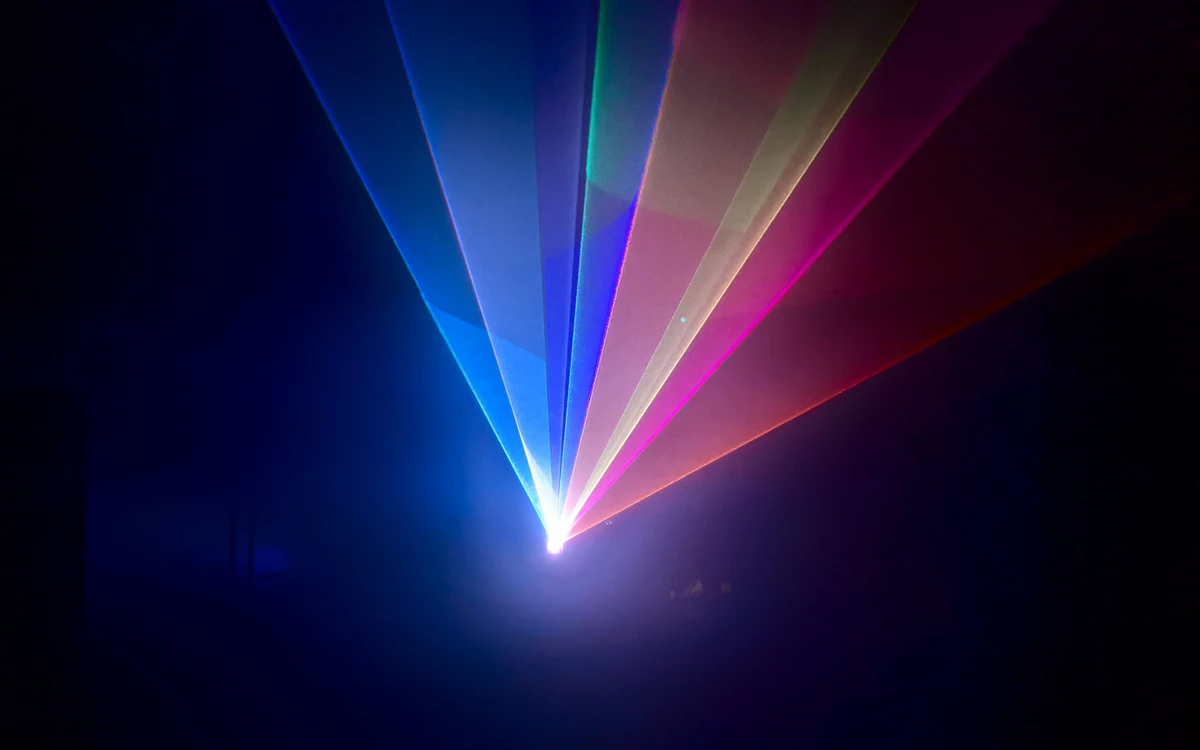

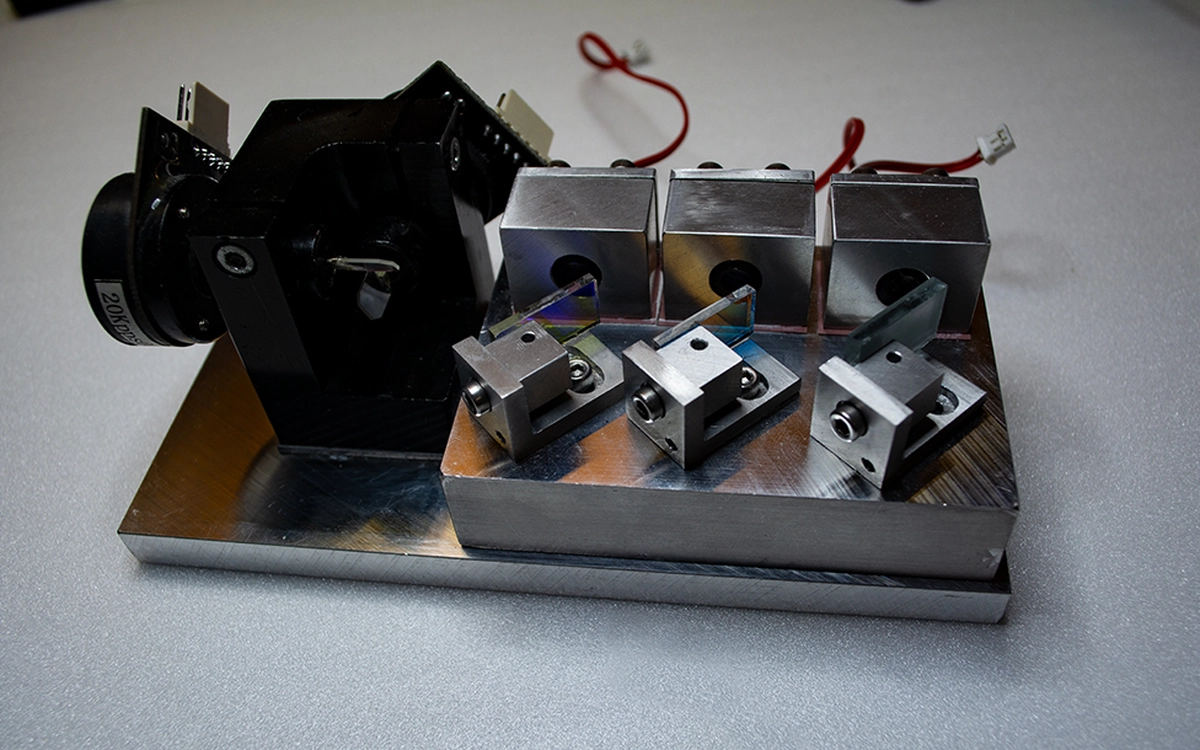

Laser graphics projectors scan a laser beam quickly across the projection area. Because of persistence of vision, the moving beam is perceived as a still vector frame. Multiple frames are then combined to create effects and animations. The beam is usually steered using a mechanical deflection assembly, where two mirrors are arranged orthogonally to allow for two axis scanning. Usually closed-loop galvanometers are used to allow fast, precise movement. I chose a cheap ready-made beam steering assembly for this project.

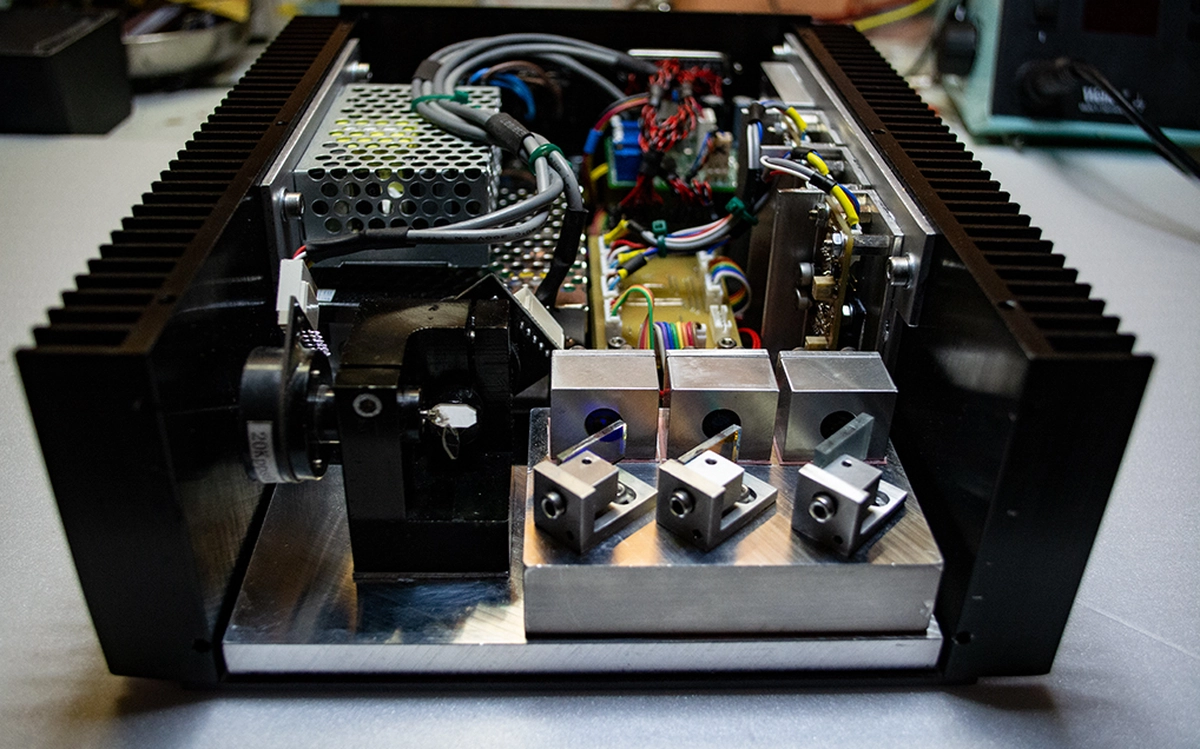

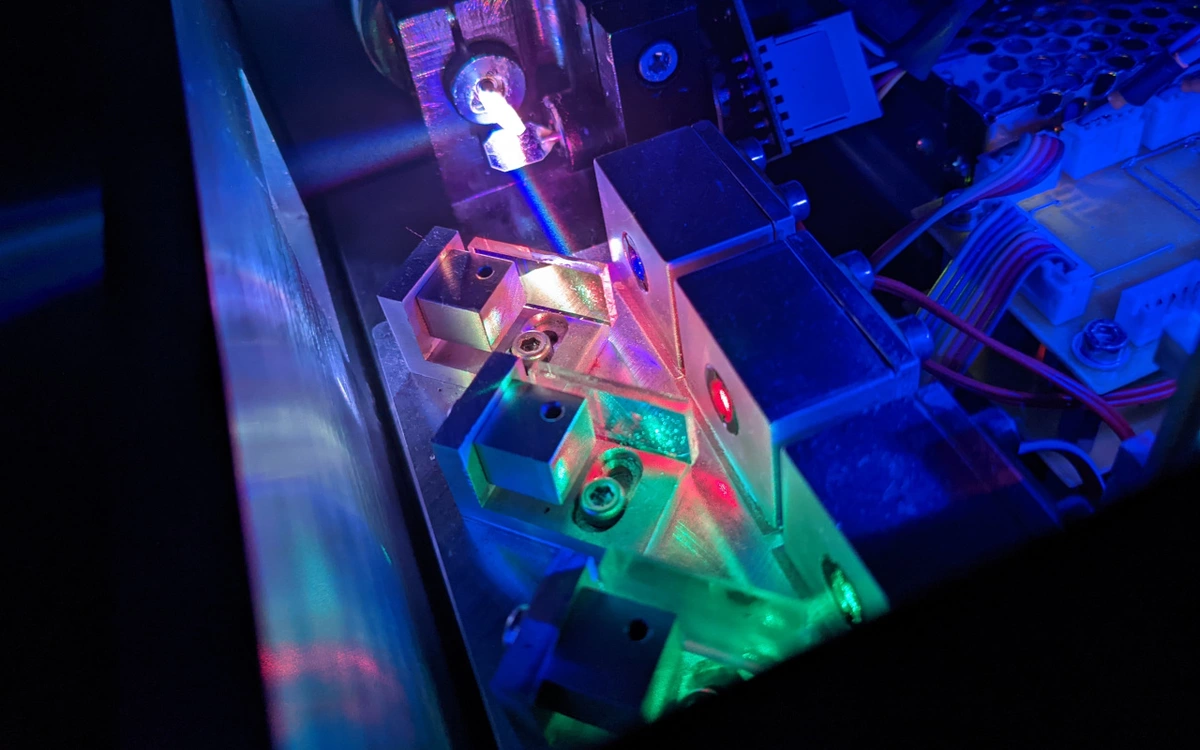

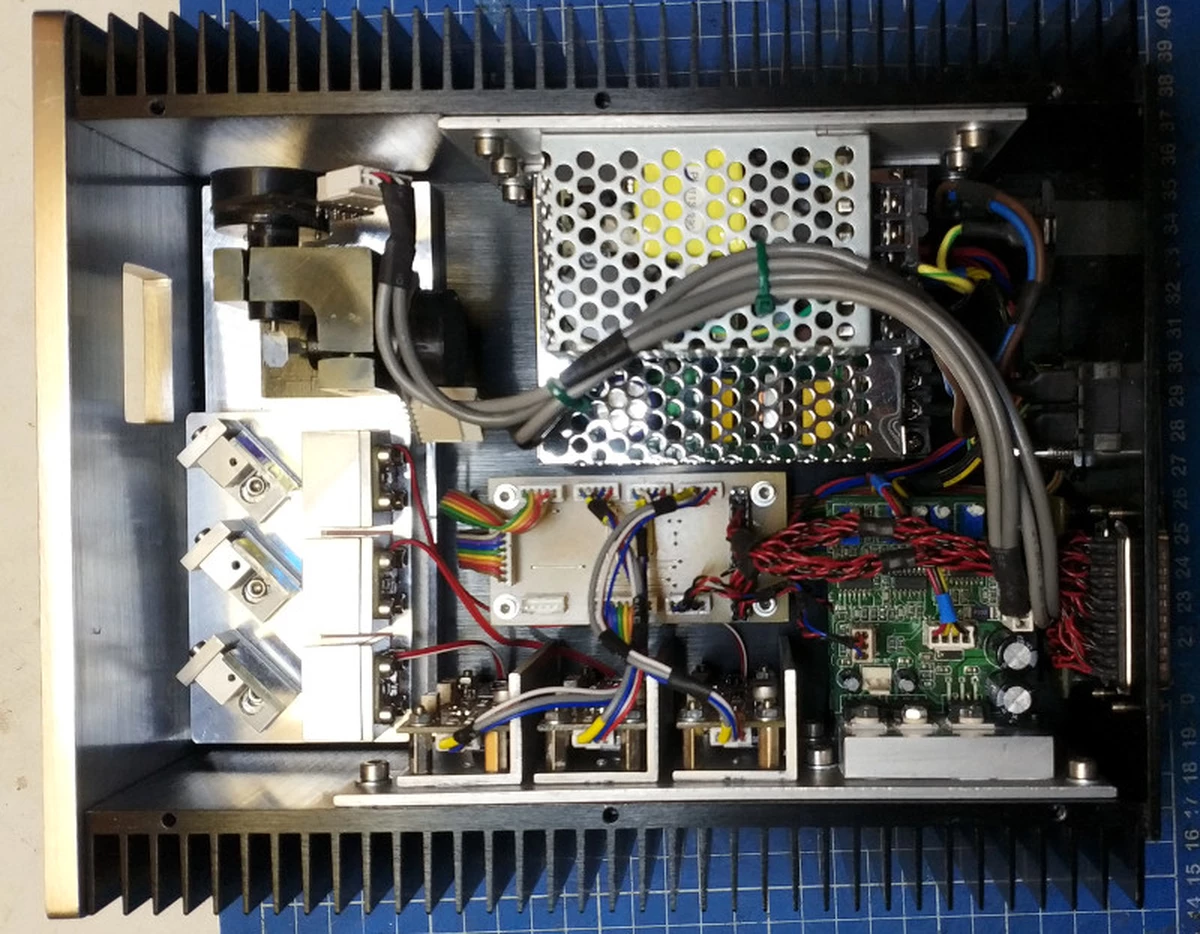

Different colors are additively combined by overlaying red, green and blue laser light. The lasers are modulated to draw separate line segments. Many modern projectors also allow analog modulation of the lasers to mix intermediate colors.I chose three diode laser emitters for this project. The total white light emission power of the system is roughly 200mW. Single mode laser diodes were chosen to allow for low beam divergence. The optical components were mounted on a 20mm machined aluminium plate to prevent mechanical distortion and reduce thermal resistance. I machined aluminium mounting blocks for the laser diodes and adjustable optics mounts. The beams are collimated using 3-piece lens assemblies.

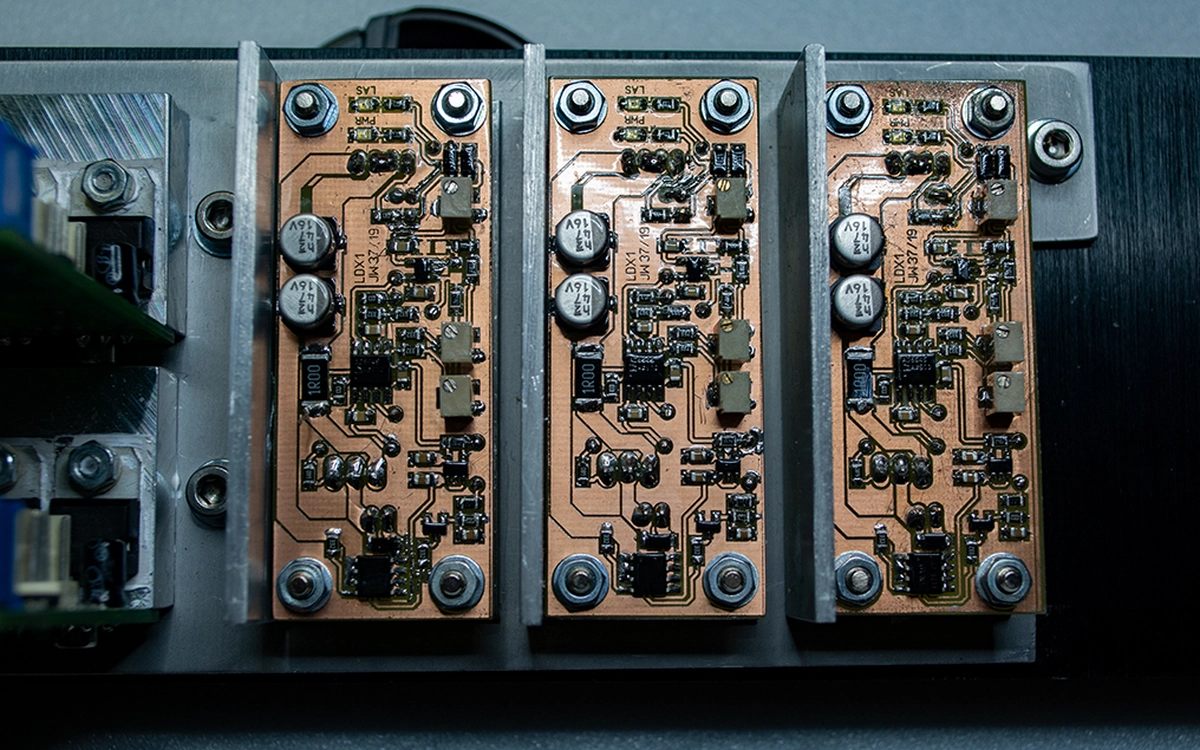

I designed low-side constant current diode drivers. Diode current can be modulated in an analog fashion with roughly 300kHz bandwidth. An offset current is added to compensate threshold current and linearize the laser's modulation response. The offset current is clamped to zero when no modulation signal is observed to ensure zero laser emission. I also added some signal conditioning to ensure clean step response.

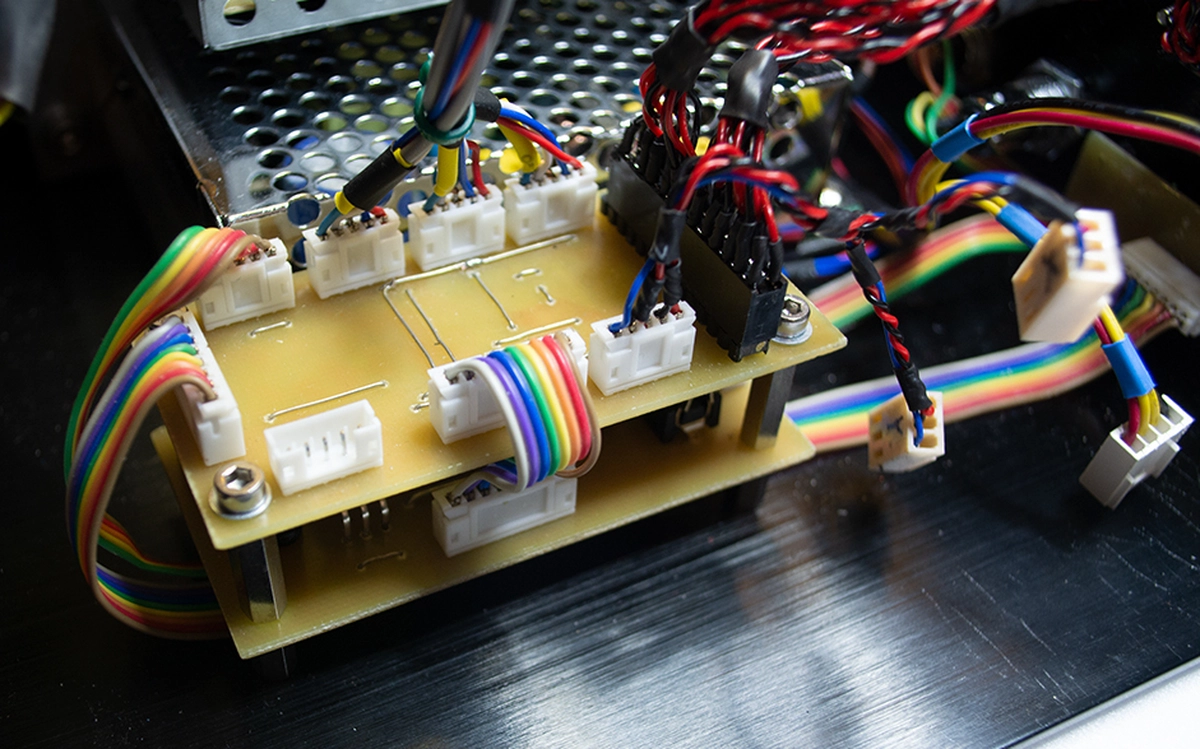

The international laser display association ILDA defines the ILDA Standard Projector (ILDA ISP) interface providing differential input for beam steering and laser modulation, as well as various logic level safety signals. I designed an interface board with differential to single ended conversion and a MCU to handle safety logic.